Blog

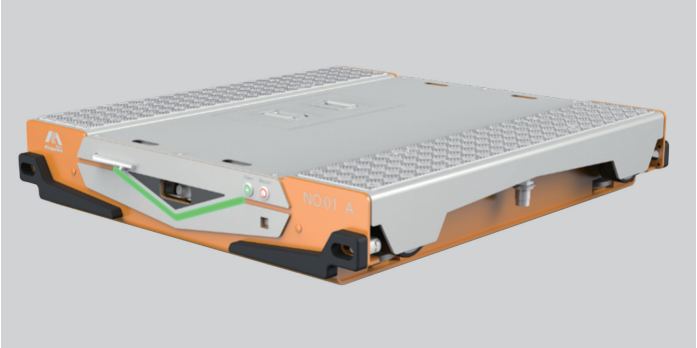

En el acelerado panorama logístico actual, maximizar la densidad de almacenamiento y optimizar las operaciones no es solo una ventaja, sino una necesidad. Presentamos los sistemas de estanterías shuttle: la solución automatizada que transforma la forma en que los almacenes gestionan el almacenamiento de gran volumen. Pero ¿qué los hace tan revolucionarios? Analicemos las principales ventajas y los escenarios ideales donde las estanterías shuttle destacan.

🚀 Ventajas clave de los Shuttle Racks

Utilización del espacio inigualable

Al eliminar los pasillos tradicionales de montacargas, los sistemas de transporte alcanzan una densidad de almacenamiento de hasta el 90 %. El espacio vertical se optimiza al máximo con configuraciones de gran altura.

Operaciones ultrarrápidas

Las lanzaderas automatizadas recuperan y almacenan palés en segundos, sin necesidad de esperar montacargas ni operarios. El rendimiento aumenta entre un 40 % y un 60 % en entornos de alto volumen.

Mayor seguridad y reducción de daños

La mínima intervención humana se traduce en menos accidentes y casi cero daños en los productos. Los almacenes reportan tasas de incidentes hasta un 80 % más bajas.

Control de inventario de precisión

El seguimiento en tiempo real a través de la integración de WMS garantiza un perfecto cumplimiento de FIFO/LIFO, fundamental para productos perecederos o productos sensibles a lotes.

Eficiencia laboral

Un operador puede gestionar varios pasillos de forma remota, lo que reduce los costos laborales y aumenta la productividad.

🏭 Donde los Shuttle Racks ofrecen el máximo impacto

Instalaciones de almacenamiento en frío: optimice el uso de energía en entornos con temperatura controlada donde la velocidad y la densidad son primordiales.

Distribución de bebidas y alimentos: Manejar altos volúmenes de SKU con fechas de vencimiento estrictas (ejecución FIFO perfecta).

Centros logísticos de comercio electrónico: acelere el procesamiento de pedidos durante las temporadas altas con operaciones automatizadas las 24 horas, los 7 días de la semana.

Almacenamiento intermedio de fabricación: gestione materias primas o productos terminados con una rotación de stock perfecta.

Almacenes Farmacéuticos: Garantizar la trazabilidad y el cumplimiento en entornos regulados.

💡 ¿Cuándo debería considerar los sistemas de transporte?

Sus instalaciones gestionan más de 500 movimientos de pallets diariamente.

Se está expandiendo verticalmente (altura libre > 10 m).

La precisión y la rotación del inventario no son negociables.

La escasez de mano de obra o las preocupaciones por la seguridad están aumentando los costos.

Consejo profesional: combine los estantes de transporte con el seguimiento RFID y un software de almacén impulsado por IA para lograr visibilidad de la cadena de suministro de extremo a extremo.

🌟 En resumen

Los sistemas de estanterías lanzadera no son solo almacenamiento: son una mejora estratégica para almacenes listos para dar el salto a la eficiencia automatizada. Al combinar una densidad excepcional, precisión robótica e integración inteligente de software, convierten las operaciones de almacenamiento en una superpotencia competitiva.

¿Listo para liberar todo el potencial de tu almacén? La revolución de las lanzaderas te espera.

¿Quieres una versión optimizada para LinkedIn, un análisis técnico profundo o traducida a otro idioma?

Por Daphne Wang

12 de diciembre de 2025

Add: NO.409 West Jianshe Road, Economic Development Zone, Jinhu County, Jiangsu Province, China

Derechos de autor

2026@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd Reservados todos los derechos.

mapa del sitio

| Blog

| Xml

| política de privacidad

RED SOPORTADA

RED SOPORTADA